1.Machinery Overview

2.Features

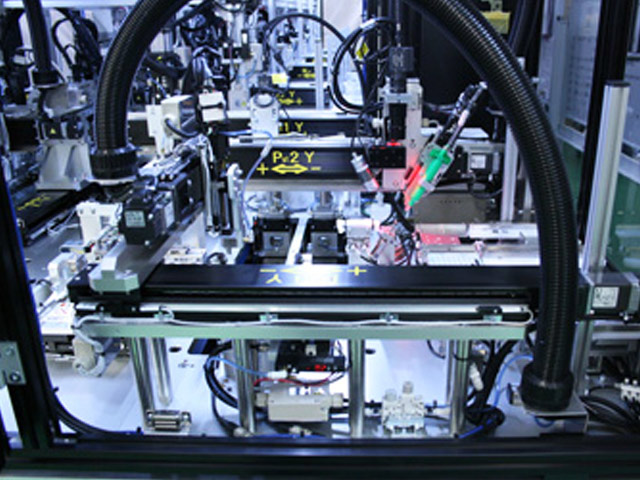

- High-precision control enabled by combining servo motors with imaging equipment

- Flexible customization is possible by incorporating requests from the device design phase

- Control programs can also be flexibly customized to meet requests

PAT.P

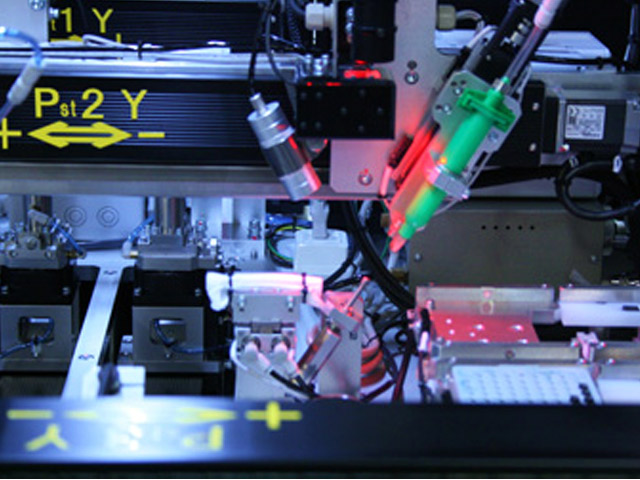

3.Device Precision

| Lowest teaching input increment | 1um |

| Axis Precision |

Main Axis1um YZ Axis(Part transportation assembly axis) 1um * Axis-adherence precision set at the time of teaching |

| Repetition Precision | Main Axis±0.001mm YZ Axis±0.001mm * The repeat accuracy within a certain scope and at a certain speed when operated repeatedly |